COLLABORATIVE ENGINEERING

FOR COMPOSITES

CATFIBER supports designers and manufacturing programmers for automated composite manufacturing.

Unlock the full value of composites automation with a co-design-driven solution

Gain a competitive edge by mastering complexities of automated composite manufacturing process (automated fiver placement – AFP / Automated tape layering / FW…. and related combinations) — faster and more efficiently. Our solution enables engineering teams to faster ramp up their expertise, with tools suit that combine design, simulation, and manufacturing engineering capabilities in a single digital environment.

Break down silos between disciplines with streamlined collaboration across modeling and simulation (stress analysis), product design, and process planning. By embedding process intelligence directly into the design phase, teams can validate feasibility early and avoid costly iterations later on.

All of this is fully integrated into the Dassault Systèmes platform, offering a unified, collaborative space where innovation moves faster — and smarter.

The Challenge – Complexity and Feasibility

Automated fiber placement processes hold major promise — in speed, consistency, and performance. But they often remain underused, due to:

- High complexity in part feasibility analysis

- Time-consuming validation cycles

- Disconnection between design, simulation, and manufacturing

- Large gaps between as-design and as-build (eBoM vs. MBoM)

Our Value – What We Make Possible

We help your teams design while maximizing tradeoff between mechanical properties, manufacturing lead-time and manufacturability right from the start in the shortest cycle time.

Our solution brings value by:

- Making feasibility assessments accessible and fast (with multiple scenarios investigation)

- Accelerating skill development for composite automated manufacturing

- Embedding process constraints into the design loop without requiring in-depth expertise

- Addressing all use cases whatever your project maturity

- Connecting design, simulation, and manufacturing teams in one environment while driving traceability

Your Benefits – What You Gain

- Up to 40% reduction in product development cycle / time-to-market

- Increase automatable part volume

- Secure highest utilization rate of your machine landscape

- Increase mechanical performances with better weight compromise

- Shorter learning curves, even for complex process: faster feasibility definition

- Reduce physical prototyping by high accuracy design: Faster validation process

- Smooth multiple scenarios evaluation on the same platform with your own criteria

- Manage traceability inside the Dassault Systemes environment

- Reduce industrial risk and opening automation opportunities

Solutions

CATFIBER supports the end-to-end approach, from design to manufacturing engineering, with two separate modules DFM & MPS.

DFM (Design for Manufacturing) will take care off early development cycle phase with design and stress link capabilities while MPS (Machine Programming & Simulation) will support the final programming of the machines. Both are integrated within the Dassault Systemes environments.

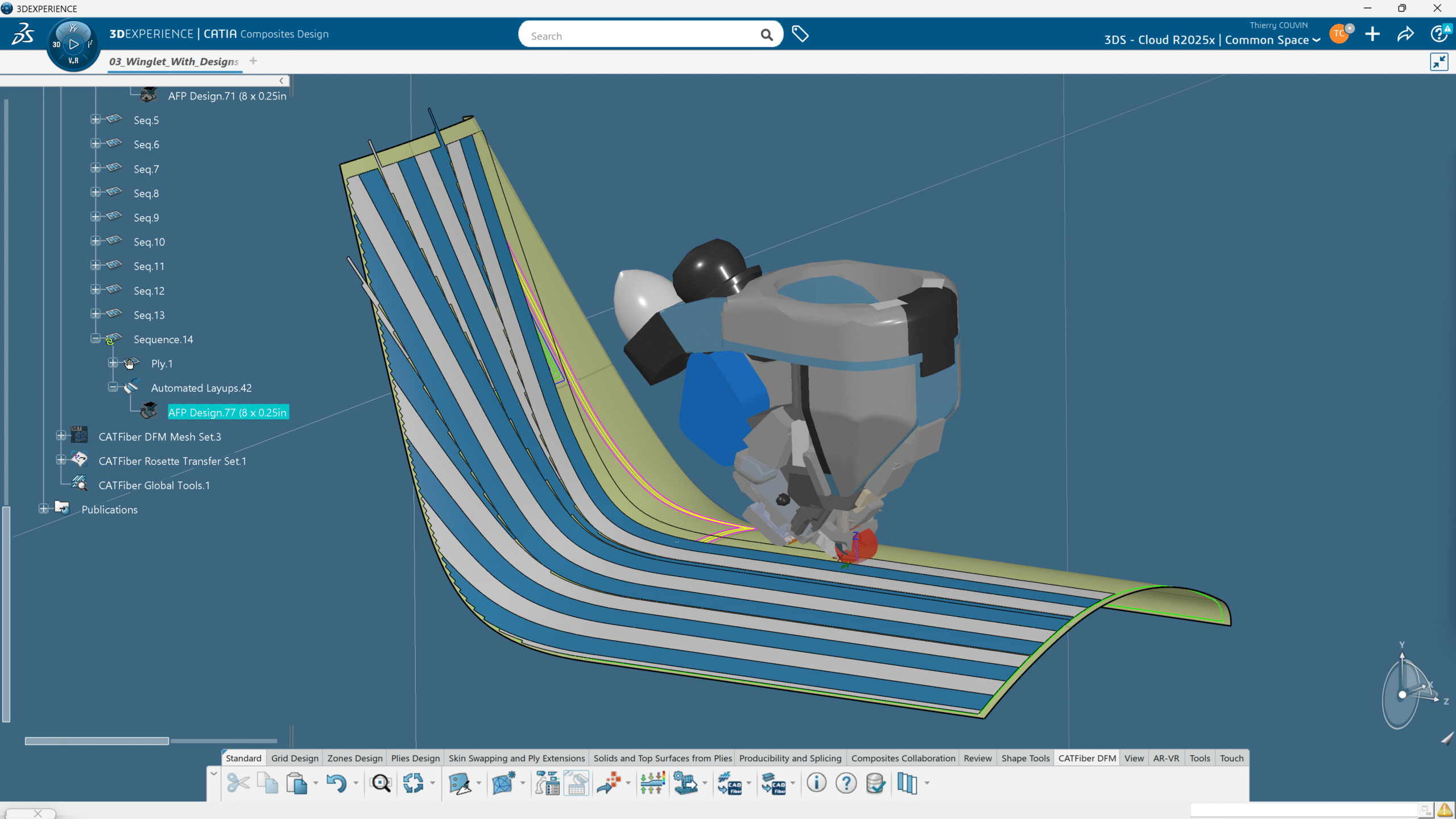

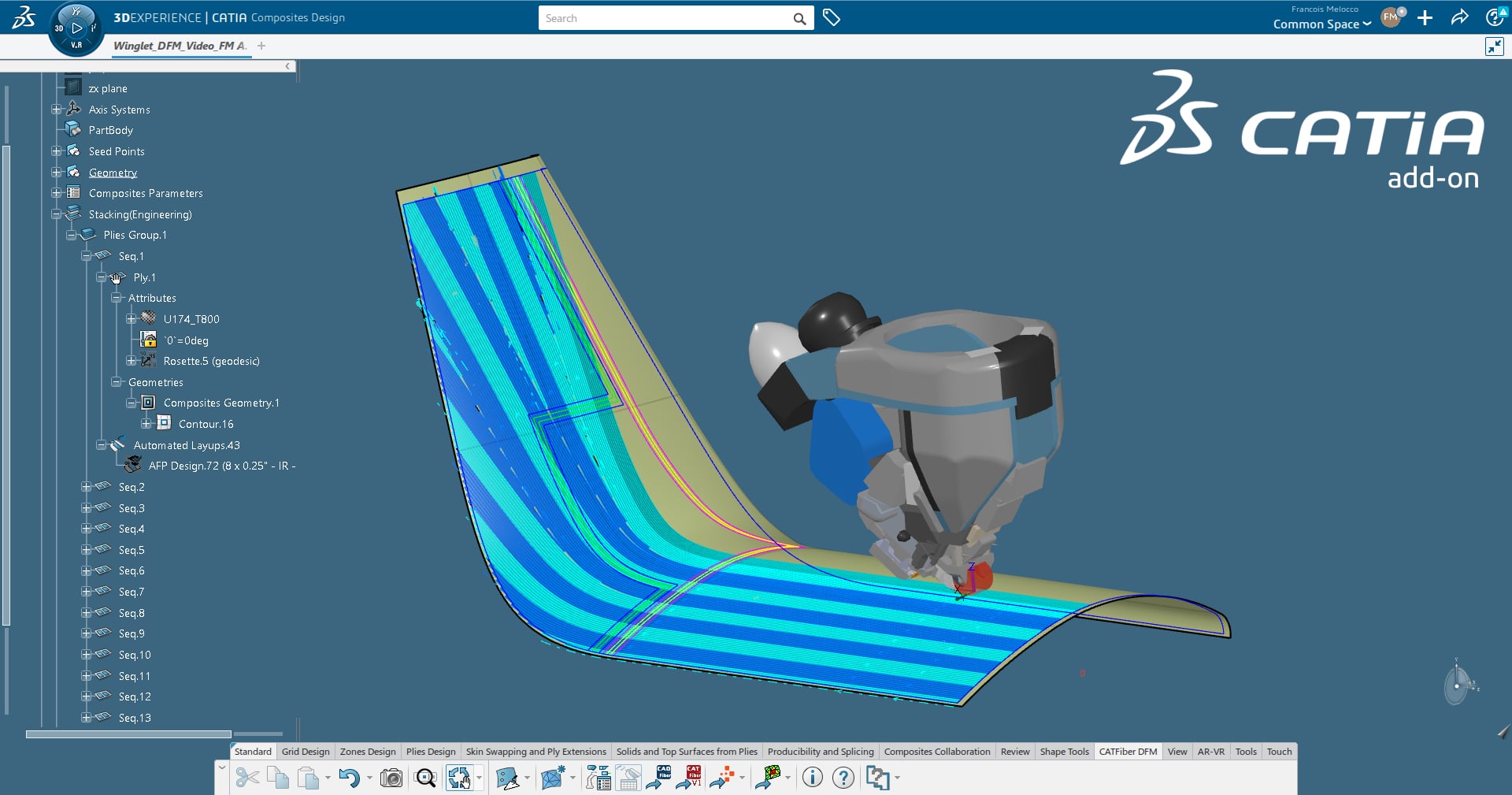

DFM (Design for Manufacturing)

CATFIBER DFM (Design for Manufacturing) is an add-on to CATIA Composites (CPD). It allows designers and/or NC programmers to extend the composites design phase down to the AFP tows design. Remaining in the CATIA environment it also allows to check if an AFP head is compatible with the AFP the AFP design. DFM is fully machine vendor independent.

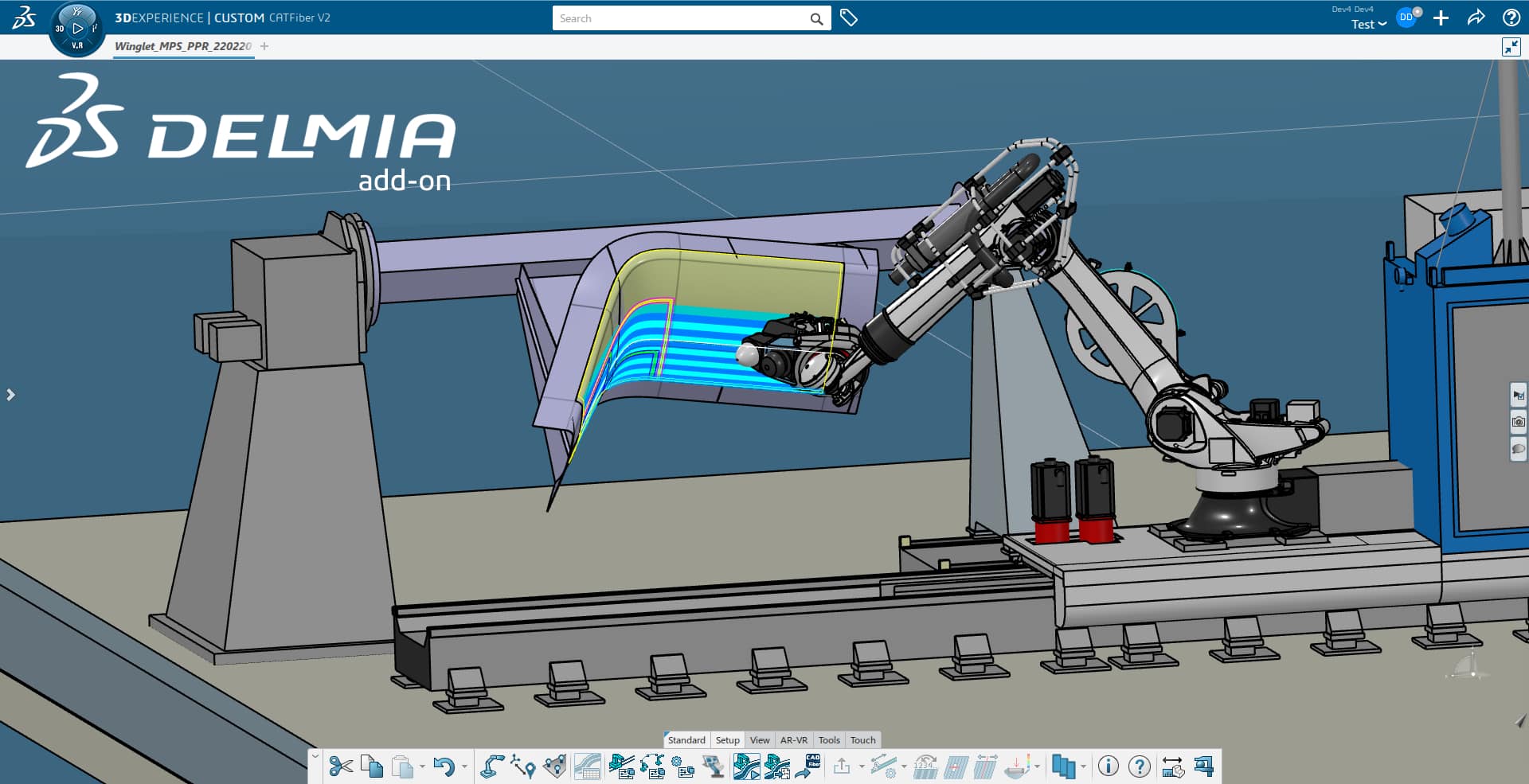

MPS (Machine Programming & Simulation)

CATFIBER MPS (Machine Programming & Simulation) is the natural extension to CATFIBER DFM in order to program the machine mouvement to lay the fibers as designed. Limited, today, to Coriolis machines, the solution will be open, in future releases, to machines from other machine vendors upon customer request.