Our solution helps you identify where automation is feasible — and where manual layup remains relevant.

Mastering automated fiber placement processes

- AFP, ATL, filament winding… automated fiber placement technologies are revolutionizing how high-performance composite structures are designed and manufactured.

- Each technology comes with specific constraints that must be understood early in the design phase.

Common Challenges

- Complex multi-physics and multi-domain constraints

- Manual iterations between design, simulation and manufacturing

- Process-specific knowledge siloed in expert teams

- Risk of late-stage incompatibilities or rework

How our solution helps

- Embed process constraints into the design model

- Connect teams through co-design and shared data

- Validate designs earlier using enriched models

- Scale your teams’ expertise through simulation and scenario exploration

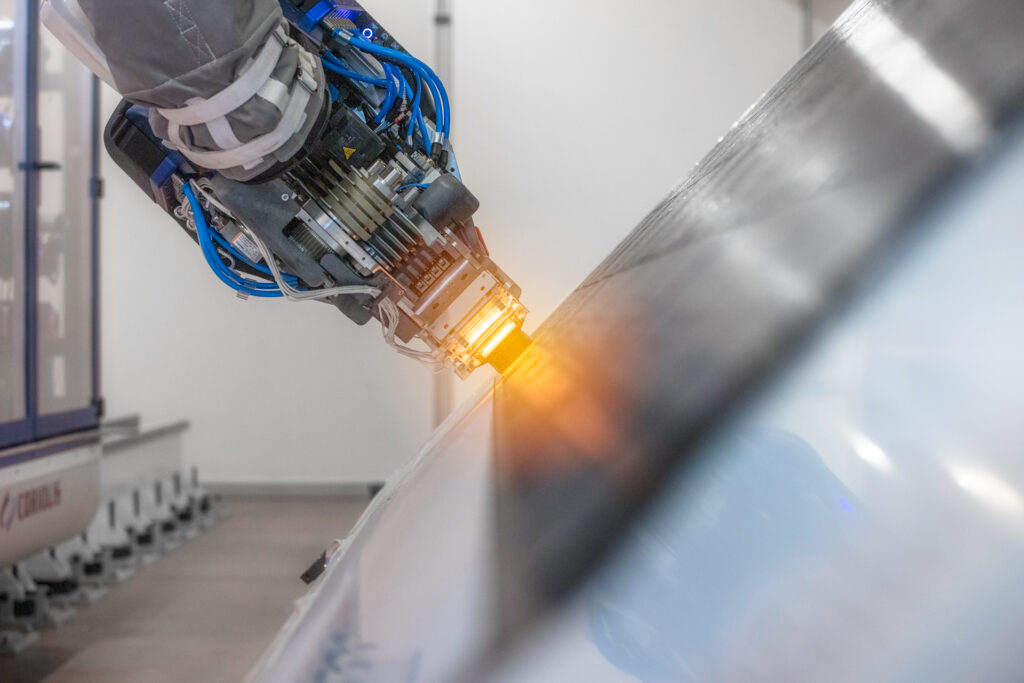

Automated Fiber Placement (AFP)

- High-precision tow placement for complex 3D shapes

- Ideal for critical aerostructures

- Demands tight control and early design/process convergence

Automated Tape Laying (ATL)

- Faster, wider material deposition

- Excellent for large, flat or gently curved surfaces

- Cost-efficient for high production rates

Available in upcoming releases

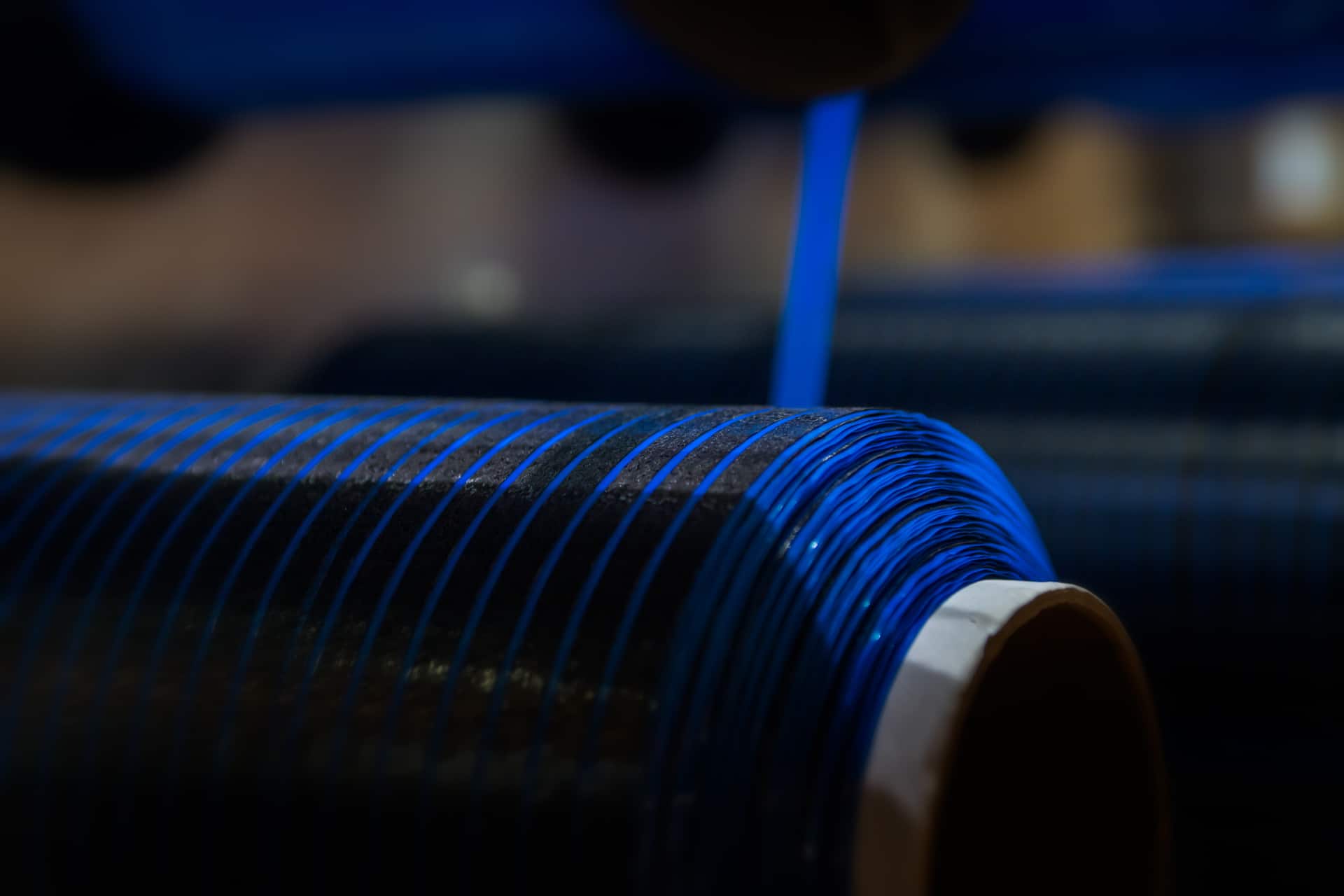

Filament Winding (FW)

- Continuous fiber winding over rotating mandrels

- High mechanical performance, especially for pressure vessels

- Geometrically constrained but highly repeatable

Available in upcoming releases

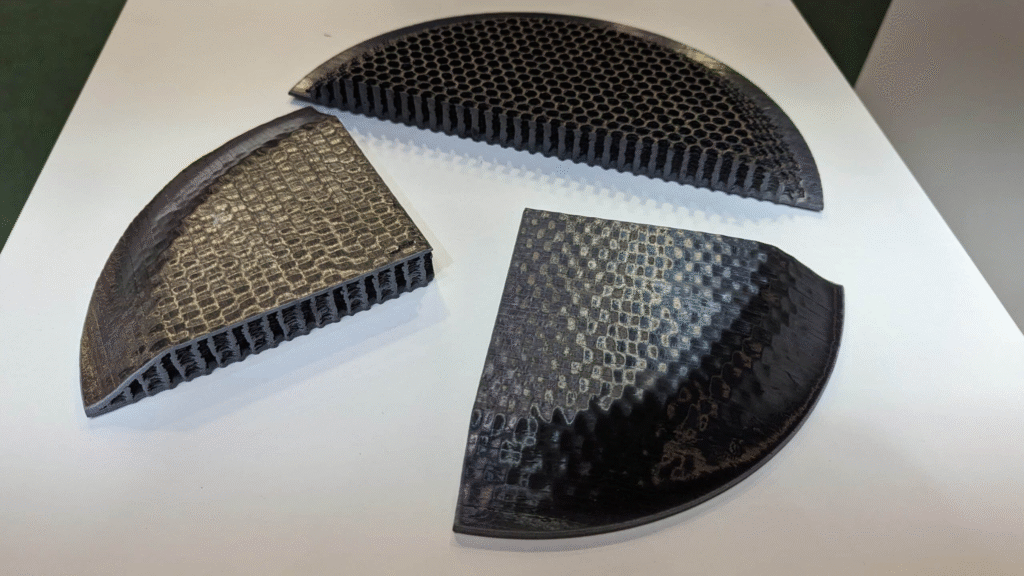

Other Advanced Methods

- Hybrid or automated draping systems

- Application-specific, requiring custom workflows

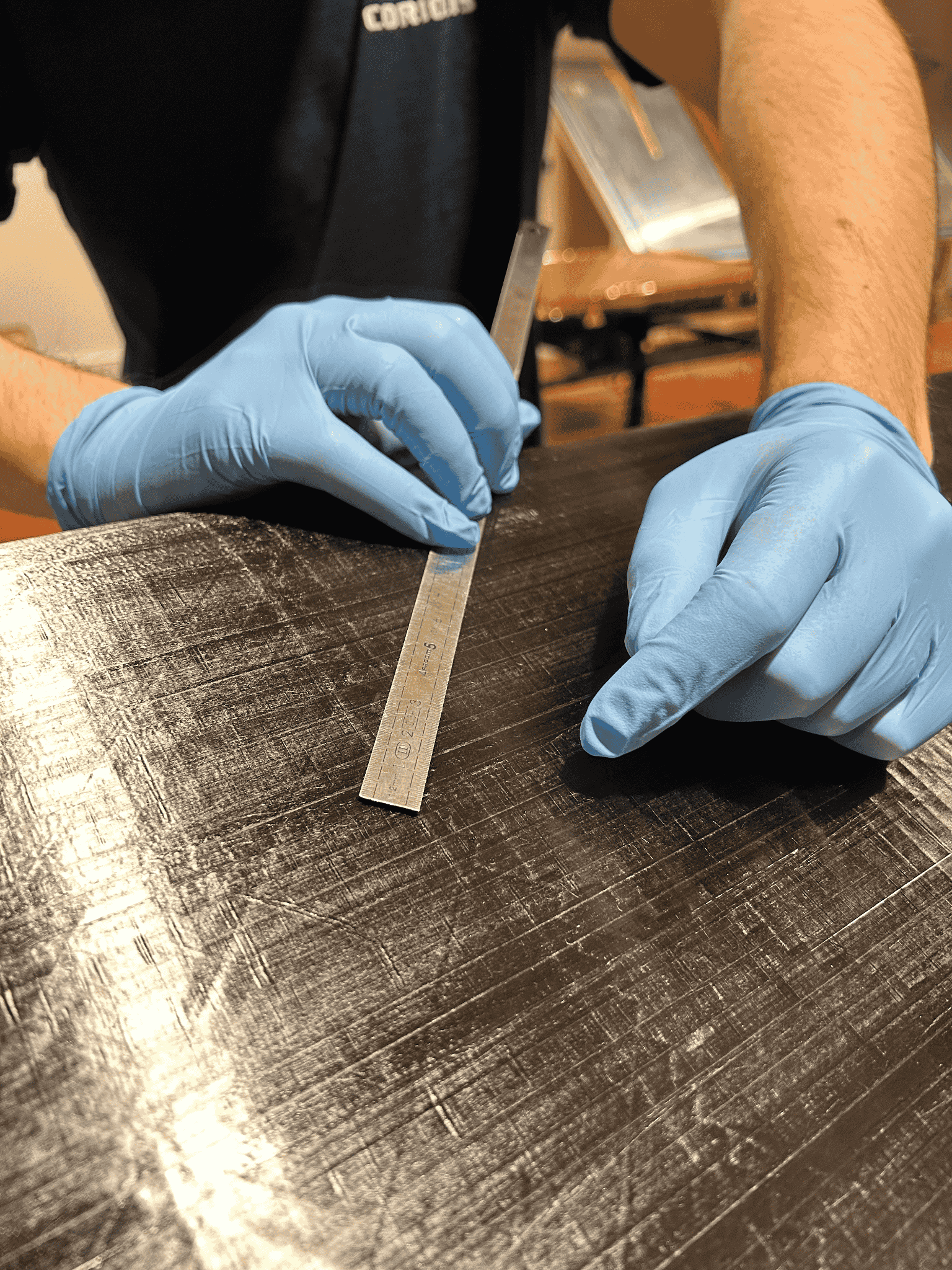

Manual Fiber Placement – For Comparison

- Offers flexibility for complex or low-volume parts

- Labor-intensive, time-consuming, and less repeatable

- No digital traceability or closed-loop validation