What makes our solution unique

Our solution brings together design, simulation, and manufacturing in a single, seamless workflow. By embedding real-world process constraints directly into design models, engineering teams can make informed decisions earlier and with greater confidence.

With a scenario-driven design approach, teams can quickly explore and compare multiple deposition or manufacturing strategies—reducing uncertainty and accelerating iteration. A closed-loop validation process feeds actual manufacturing data back into structural simulation, ensuring performance is continuously verified and aligned with production realities.

All of this is fully integrated into the 3D Experience platform, providing a unified, collaborative environment where every stakeholder works with a shared, up-to-date digital thread from concept to production.

Global benefits

- Reduce design-to-manufacturing leadtime

- Provide manufacturing process requirements as early as possible

- Maximize use of automated manufacturing

Design benefits

- Optimize mechanical properties considering manufacturing constraints

- Ease of communication between NC-programmers and designers

- Final FEA validation with “as-programmed” part definition

Process benefits

- Machine vendor agnostic solution

- Compatible with legacy machine programming solutions

- Maximum precision of CAD definition of part (AFP design fully embedded in CATIA)

Accelerate learning, real-world results

Up to 40% faster development cycles

Fewer physical prototypes through early and accurate validation

End-to-end traceability from design to production

Faster skill development across teams with a consistent, user-friendly environment

Discover our two solutions

Explore how each offering addresses specific challenges in design and industrialization—tailored to your needs and ready to deliver result from day one.

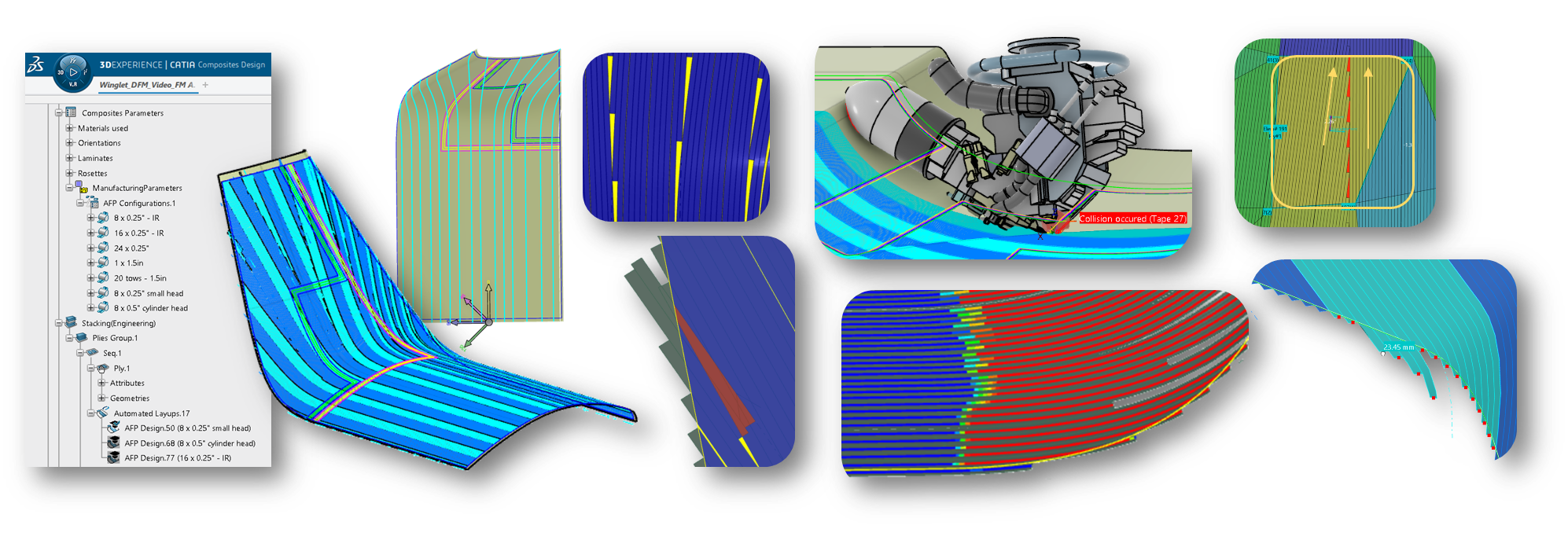

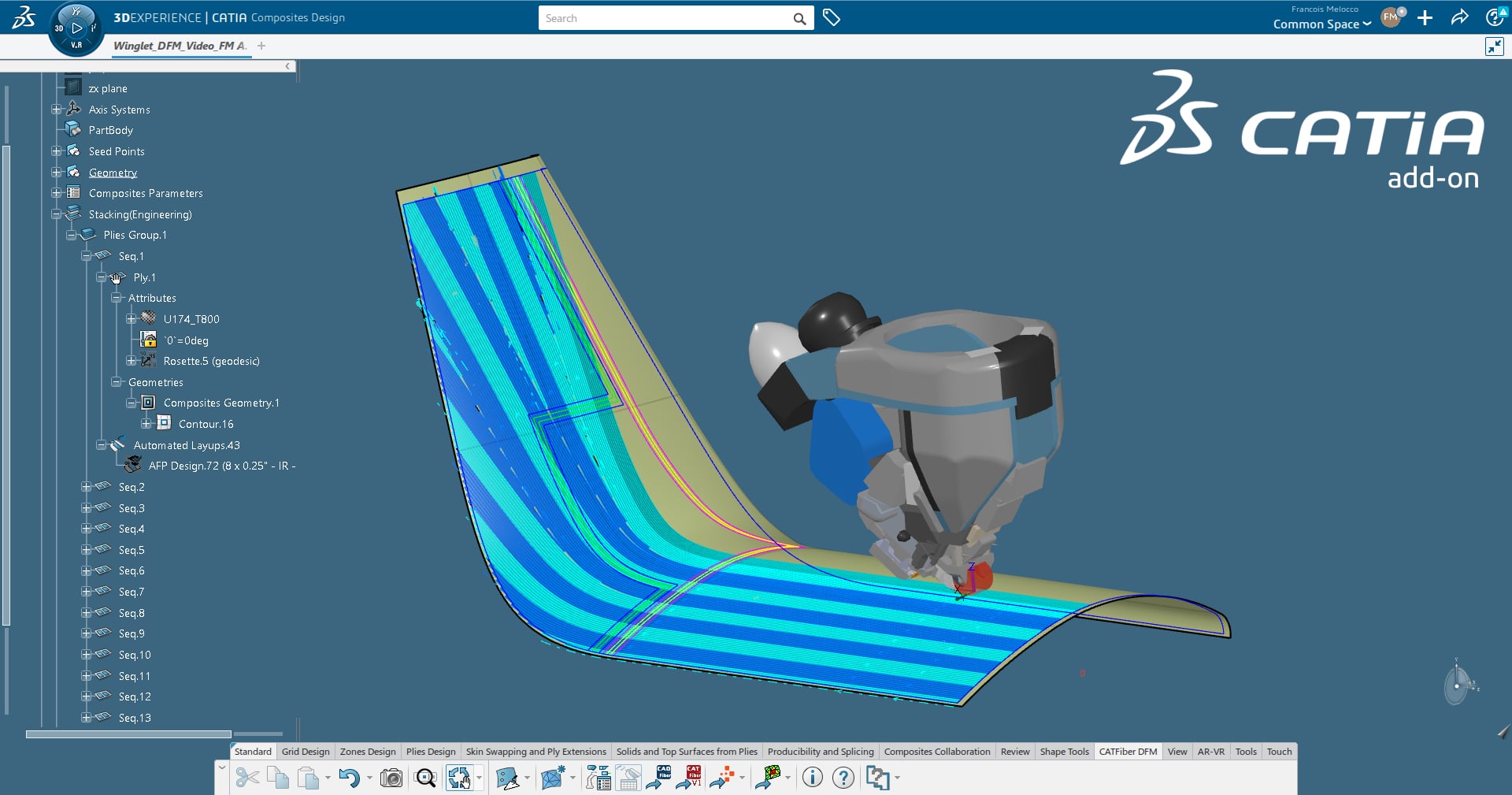

DFM (Design for Manufacturing)

CATFIBER DFM (Design for Manufacturing) is an add-on to CATIA Composites (CPD). It allows designers and/or NC programmers to extend the composites design phase down to the AFP tows design. Remaining in the CATIA environment it also allows to check if an AFP head is compatible with the AFP the AFP design. DFM is fully machine vendor independent.

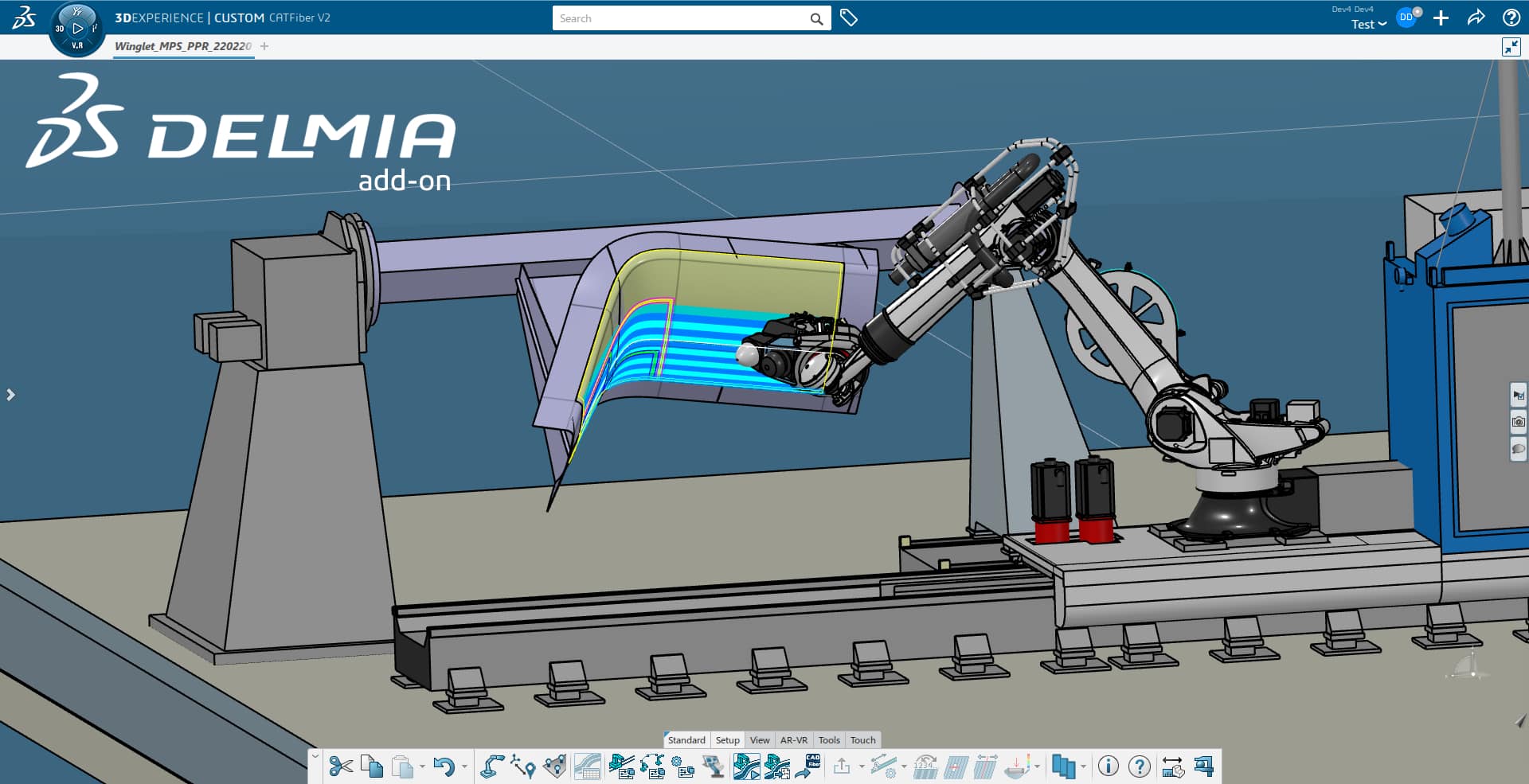

MPS (Machine Programming & Simulation)

CATFIBER MPS (Machine Programming & Simulation) is the natural extension to CATFIBER DFM in order to program the machine mouvement to lay the fibers as designed. Limited, today, to CORIOLIS machines, the solution will be open, in future releases, to machines from other machine vendors upon customer request.