Supporting strategic use of composite design.

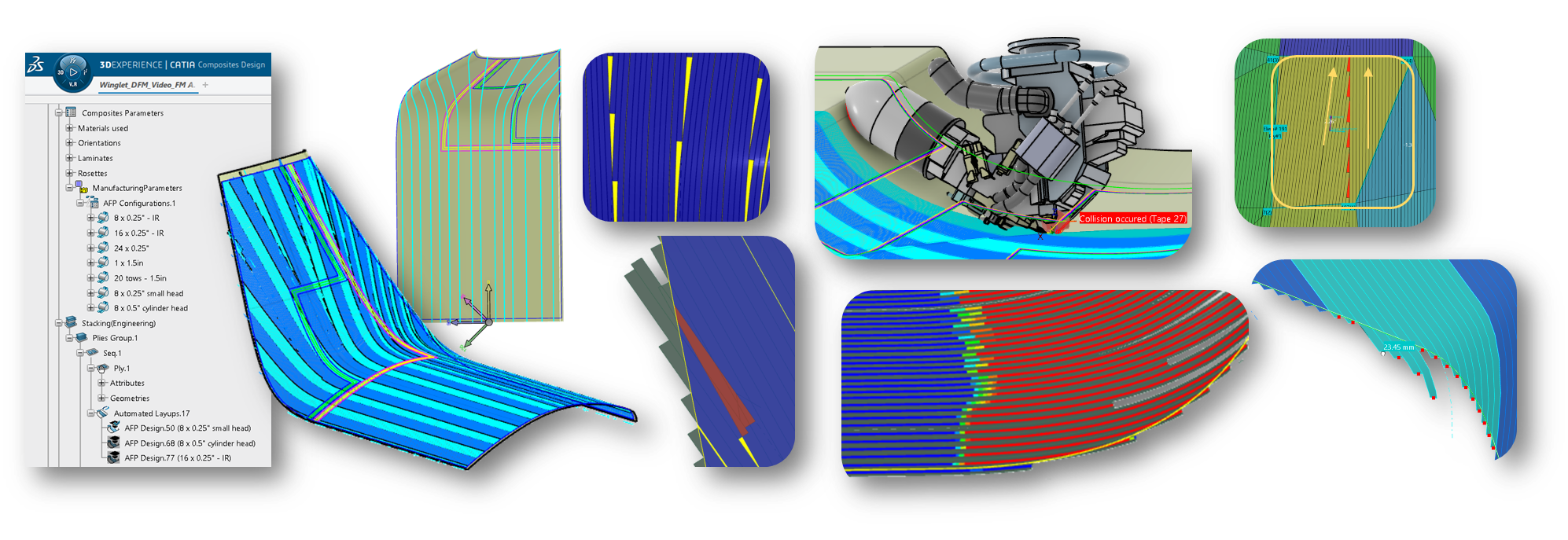

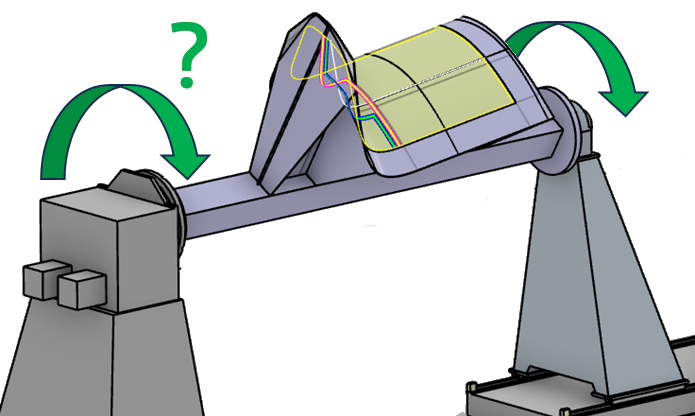

Feasibility Assessment

- Validate intricate layups early

- Minimize prototypes

- Enable true co-design across domains

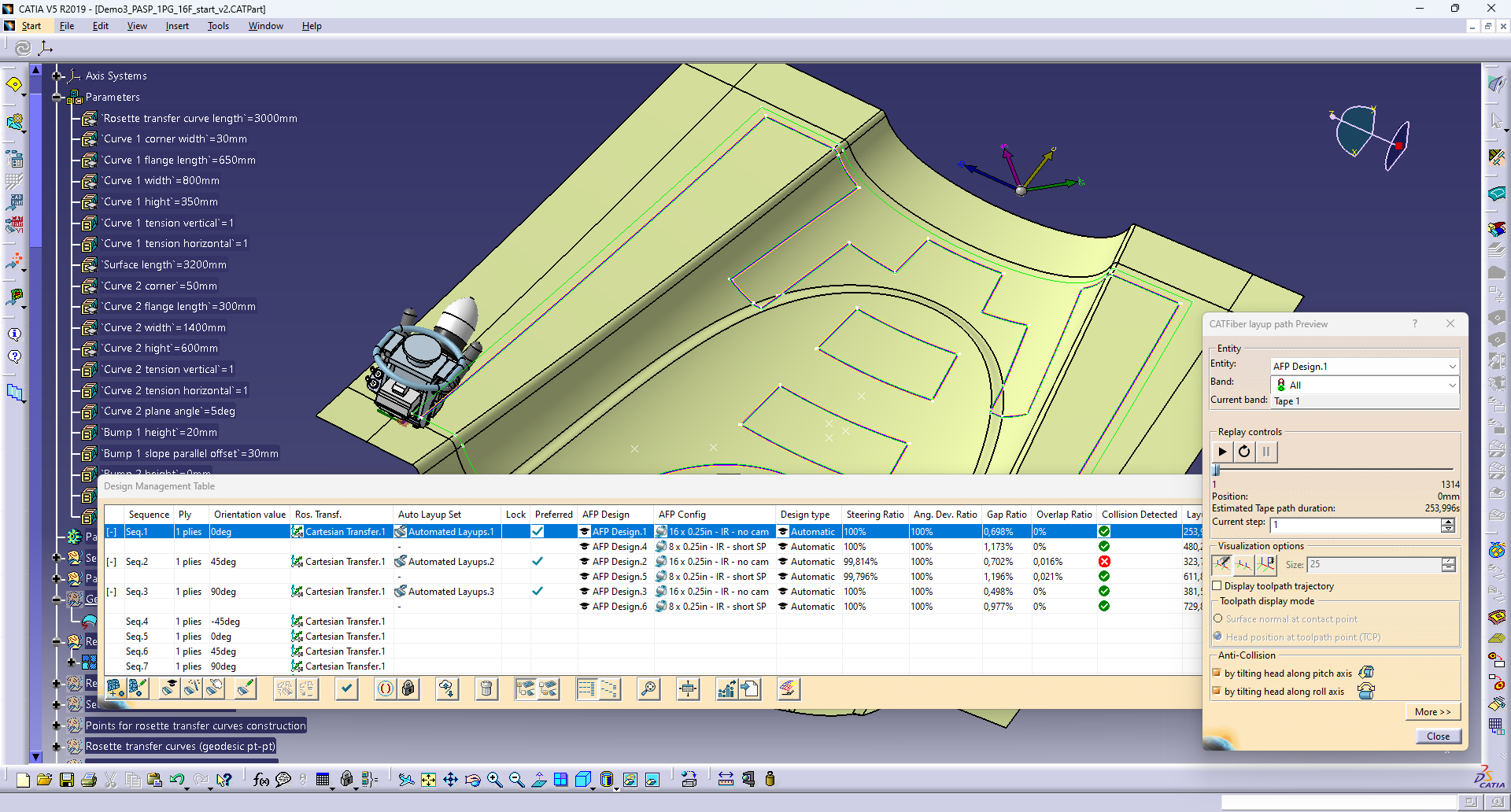

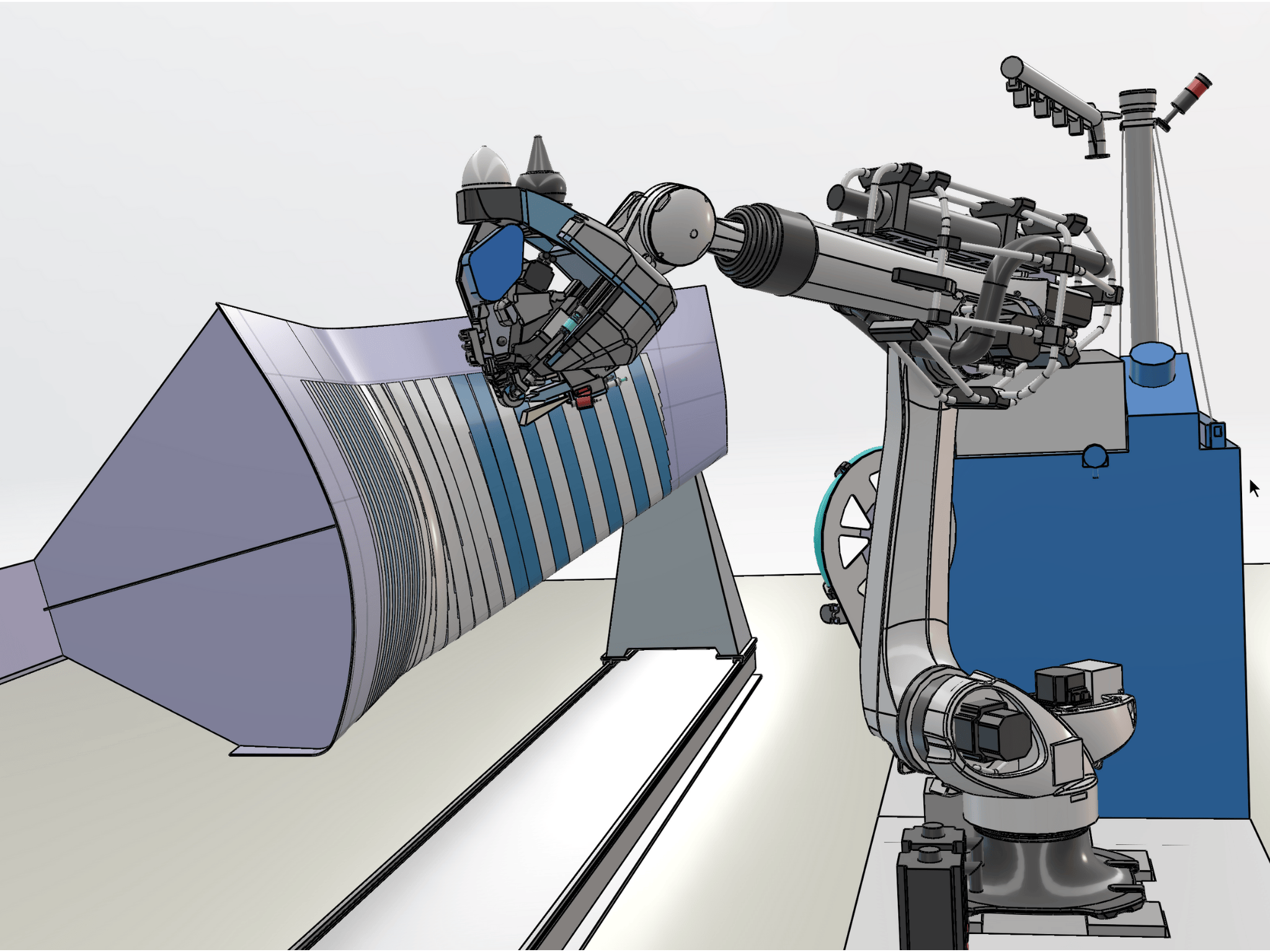

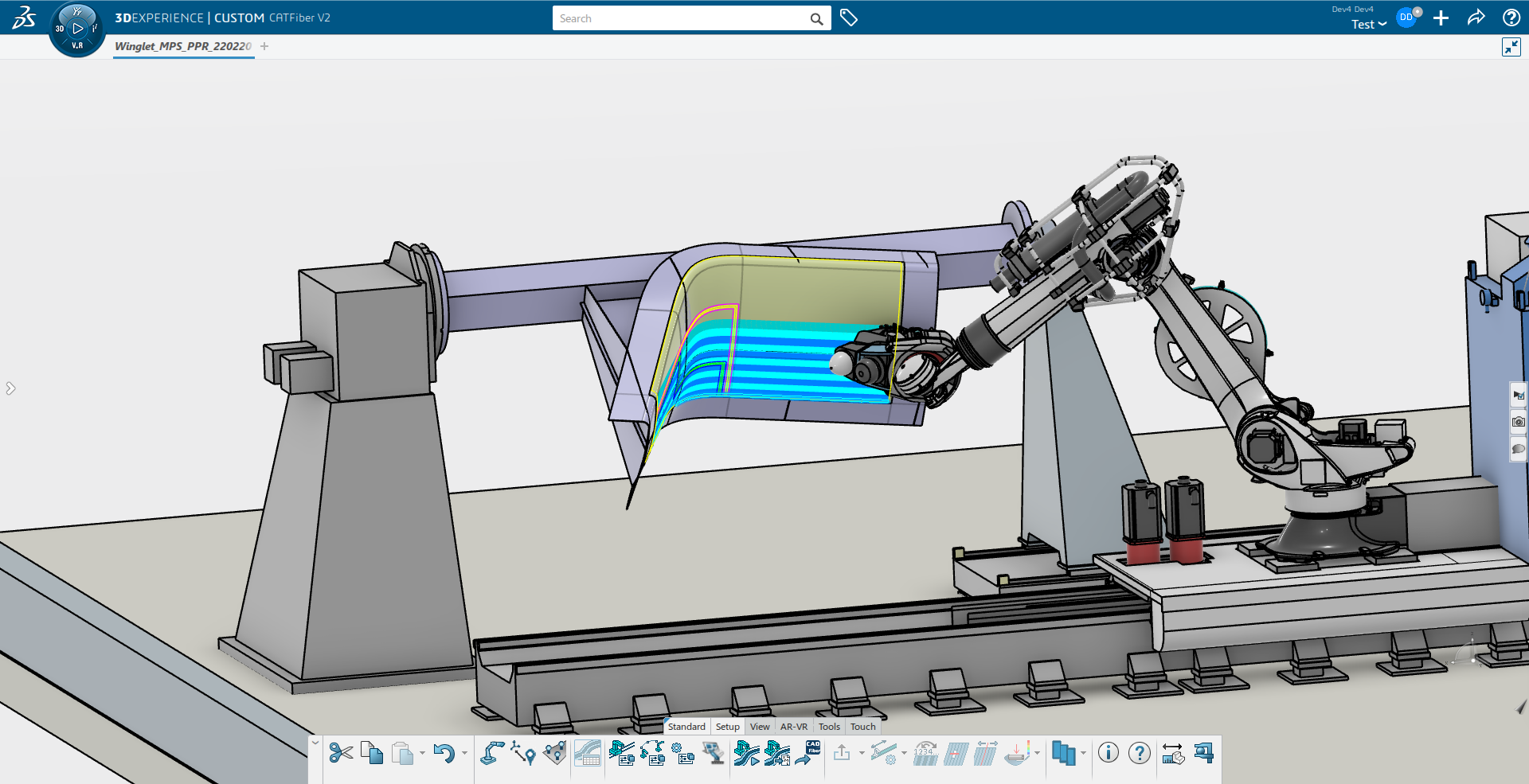

Machine & Equipment Specification

- Define layup head reach, paths, and constraints

- Quantify workspace needs

- Guide design of custom AFP/ATL equipment

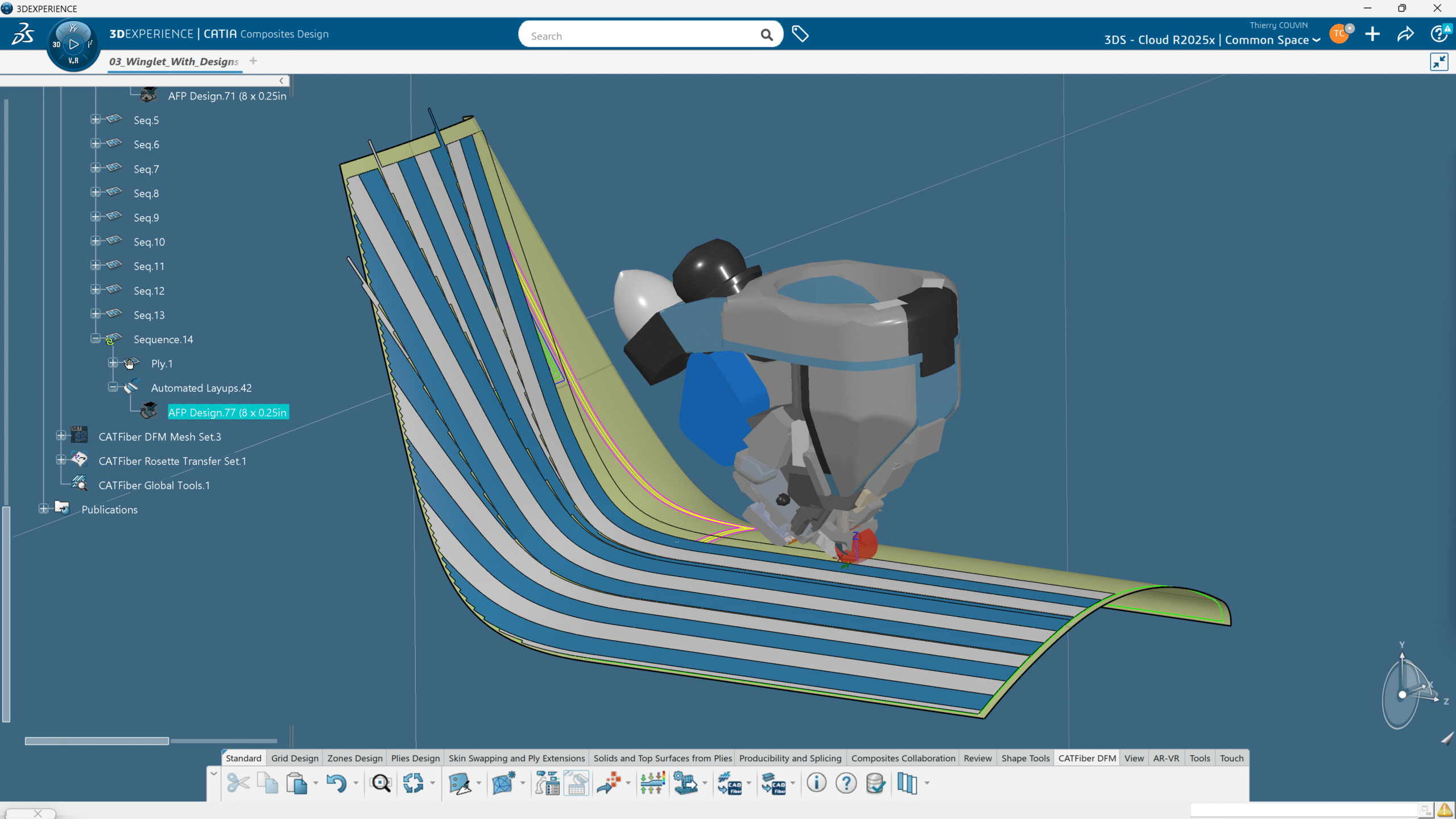

New Product Development

- Integrate automated layup from day one

- Design collaboratively with embedded constraints

- Build reusable, PLM-compliant design assets

Transition from Manual to Automated deposition

- Re-assess legacy parts for automation

- Adapt designs for compatibility

- Reduce manual labor and variability

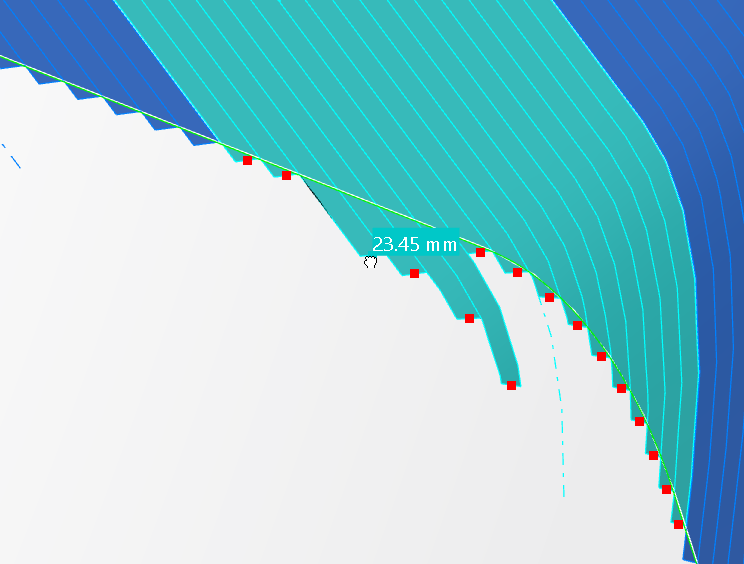

Process Optimization

- Switch to faster layup methods (e.g. AFP to ATL)

- Refine fiber paths, reduce waste

- Improve throughput with minimal change

Design Optimization Beyond Isotropy

- Go beyond default fiber patterns

- Tailor orientation to performance

- Use simulation-driven design refinements

Supporting strategic use of composite design.